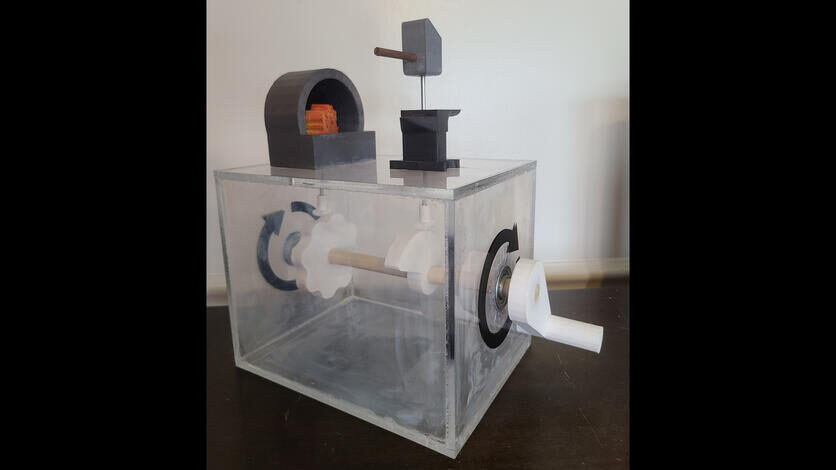

Pull-back wind-up toy car. The toy demonstrates the STEM concept of the conservation of energy by transforming stored elastic structural energy (of a spring) into kinetic energy that moves that car.

You have to hand it to Assistant Professor Georges Ayoub for finding ways to make engineering education both rigorous and fun. A couple semesters ago he had his students concept, design and manufacture original board games — a highly detailed process that involves a surprisingly wide range of skills in the engineer’s toolbox. He got such good feedback that this year, he decided to up his game with a follow-up project in one of his manufacturing classes. The challenge: build STEM learning toys and then gift them to the Dearborn Toy Library, a local nonprofit that lets kids checkout toys, including many educational ones.

More Info

Interested in learning more about the Dearborn Toy Library? Visit their website to get more information about borrowing toys or making a toy donation.

Ayoub hatched this plan with Executive Director Mary Gladstone-Highland, who co-founded the toy library with her son a few years back. (Ayoub also serves on the board.) She says there’s a ton of interest in STEM toys nowadays, but there’s often a perception among parents that they’re prohibitively expensive. She’s not sure if that’s actually true — or if other, flashier, highly marketed toys are just better at attracting kids’ attention and parents’ credit cards. Regardless, that makes STEM toys a great fit for the toy library. Since folks can borrow them instead of having to buy them outright, it stretches families’ budgets and creates a lot more access to educational toys.

Making a bunch of STEM toys and gifting them to the library sounded like a great idea, but Ayoub admits he wasn’t sure what they were going to end up with. The process of not only designing, but building a finished toy that a kid is going to enjoy, not hurt themselves with, and also not break in two minutes is a pretty tall challenge for a single semester. Students would have to quickly work through the design and prototypes phases. And then they’d actually have to manufacture a finished product — which would involve learning to use various manufacturing systems in our MSEL lab, including 3D printers, welding equipment and woodworking tools.

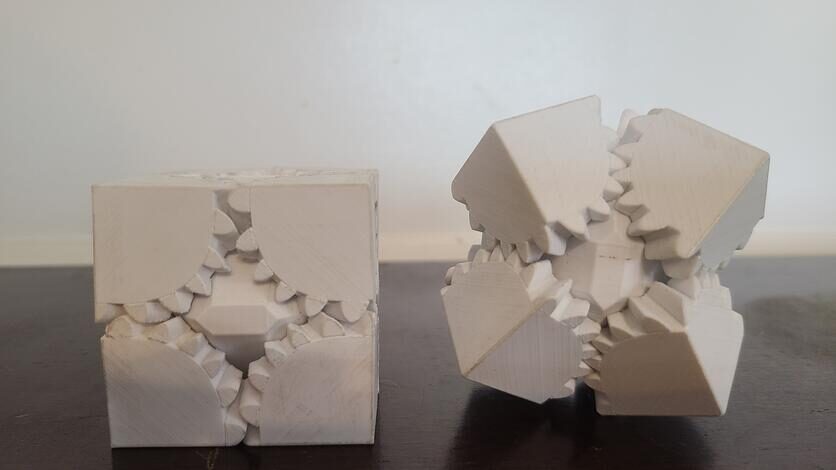

As it turned out, Ayoub didn’t have anything to worry about. The students came through with some pretty amazing, sturdily built toys that he calls “beautiful and thoughtfully designed.” One team created a version of a Do Nothing Machine — a classic STEM toy that dates back to the time of the Greek mathematician, physicist and engineer Archimedes. Jacob Gaudette and his partners chose another classic — Newton’s cradle. The line of metal spheres is strung and suspended from a small scaffold such that when you draw back the sphere on one end and release it, it strikes the others, sending the one on the opposite end flying and setting off a chain reaction of collisions. “I mean, I have a handle on the physics of what makes it work; we’ve studied all that stuff in our classes,” Gaudette says, referring to principles like the conservation of energy and conservation of momentum, which the cradle demonstrates really clearly. “But you see it happen and it still looks like magic. I would have loved to have that toy as a kid.”

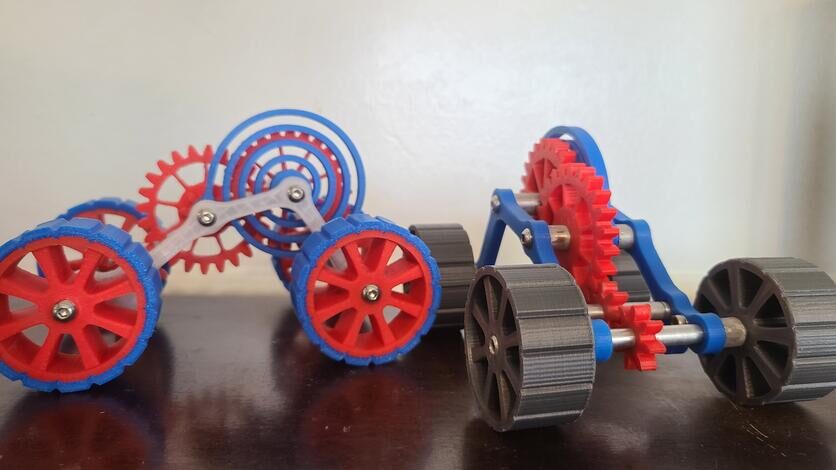

For Isabella Luckey, the toy challenge was serendipitous. She actually works for a nonprofit educational lab in Ypsilanti, where her job is building up a roster of STEM toys for their educational programming. For their class project, she and her partner set their sights on a from-scratch build of a pull-back wind-up car. It zooms forward when you release it, and since it was intended as an educational toy, they designed it without a frame so kids can see the springs and gears that make it work. During their design process, they ran into several challenges that required some quick problem solving. In one of their early prototypes, for example, they discovered if a kid wound the car forward instead of backward, it could break the spring powering the car, which inspired a little reengineering. And Luckey says they figured out that printing the wheels one at a time on multiple printers, rather than printing all four in a single print, avoided the frustration of 12-hour print runs that ended up failing a couple times. “I definitely didn’t expect that it was going to take a week to 3D-print parts,” Luckey says, smiling. “I think running into challenges like that made me realize how many iterations it takes to get things right. You don’t just come up with an idea for a design and then make it. Things just don’t move as smoothly as you expect. So I really feel like we learned a lot more having to go through the entire process.”

Ayoub loves hearing feedback like that. He’s a big believer that some skills are really difficult to learn solely through theory. When it comes to bending a piece of metal or 3D-printing a part, for example, there really is no substitute for doing it yourself, witnessing failures, and being forced to come up with alternatives. “So this whole project has strengthened my belief that learning is best done while practicing,” Ayoub says. “That goes for the IMSE students who practiced their design skills and these manufacturing processes — and for the kids who will practice science when they play with these toys.”

Other than those positive student learning experiences, you might say the kids’ impressions of the toys are the other key measure of the project’s success. On the front, Gladstone-Highland says the UM-Dearborn students are getting high marks. “We’ve already had several kids come in to play with these toys, and they’ve been fascinated by every single one of them,” she says. “I think the other thing that’s really special about this project is that there is a big a difference between a parent saying to a kid, ‘you know, you could grow up and make that toy’; and being able to say, ‘someone in your community, who is really not that much older than you made this toy.’ For the kids who are borrowing them, that makes a future in which they’re the ones designing and building things that much closer a reality.”